Common problems and solutions when using glitter vinyl transfer film

Common problems and solutions when using glitter vinyl transfer film include:

1. Uneven heat transfer machine platform: This can lead to uneven temperature and pressure during the transfer process, affecting the melting and curing of the hot melt adhesive. The solution is to adjust the heat transfer machine platform to a suitable level position.

2. Uneven fabric: Uneven temperature and pressure during fabric transfer can affect the melting and curing of the hot melt adhesive. The solution is to press the fabric flat before transferring.

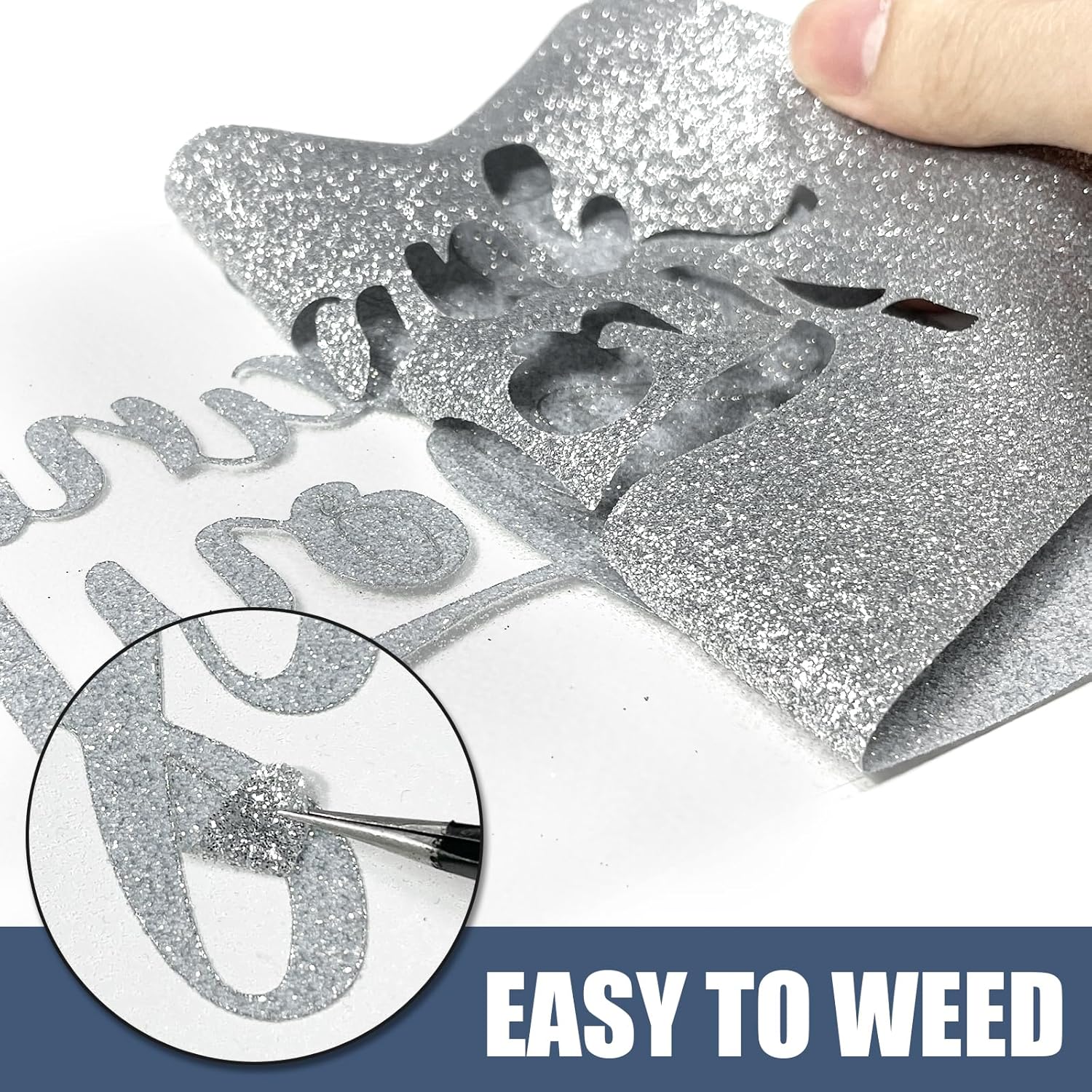

3. Too small patterns or too thin lines: The hot melt adhesive may have already melted during the engraving process. The solution is to avoid using transfer film for patterns or lines that are less than 0.5mm.

4. Waterproof fabric issues like down jacket fabrics: These fabrics have a silicone oil waterproof layer that requires a specific waterproof fabric adhesive.

5. Hot tearing after transfer: Hot tearing can cause the adhesive to not set properly, leading to poor adhesion. The solution is to cold tear the transfer film, waiting about 8 minutes before peeling off.

6. Washing test immediately after transfer: It is necessary to wait for 24 hours before conducting a washing test.

7. Insufficient pressure from the heat transfer machine: Test the pressure manually by placing a release film on the press plate and trying to pull the release film. If it moves, the pressure setting of the heat transfer machine is not enough and needs to be reset.

8. Insufficient transfer temperature: Test with a temperature gun. If a layer of fabric is added on the press plate, it is recommended to increase the transfer temperature by about 10-20 degrees.

9. Moisture in the fabric: Moisture can affect the transfer temperature and pressure, impacting the melting and curing of the hot melt adhesive. The solution is to press for more than 5 seconds to evaporate the moisture on the fabric before transferring.

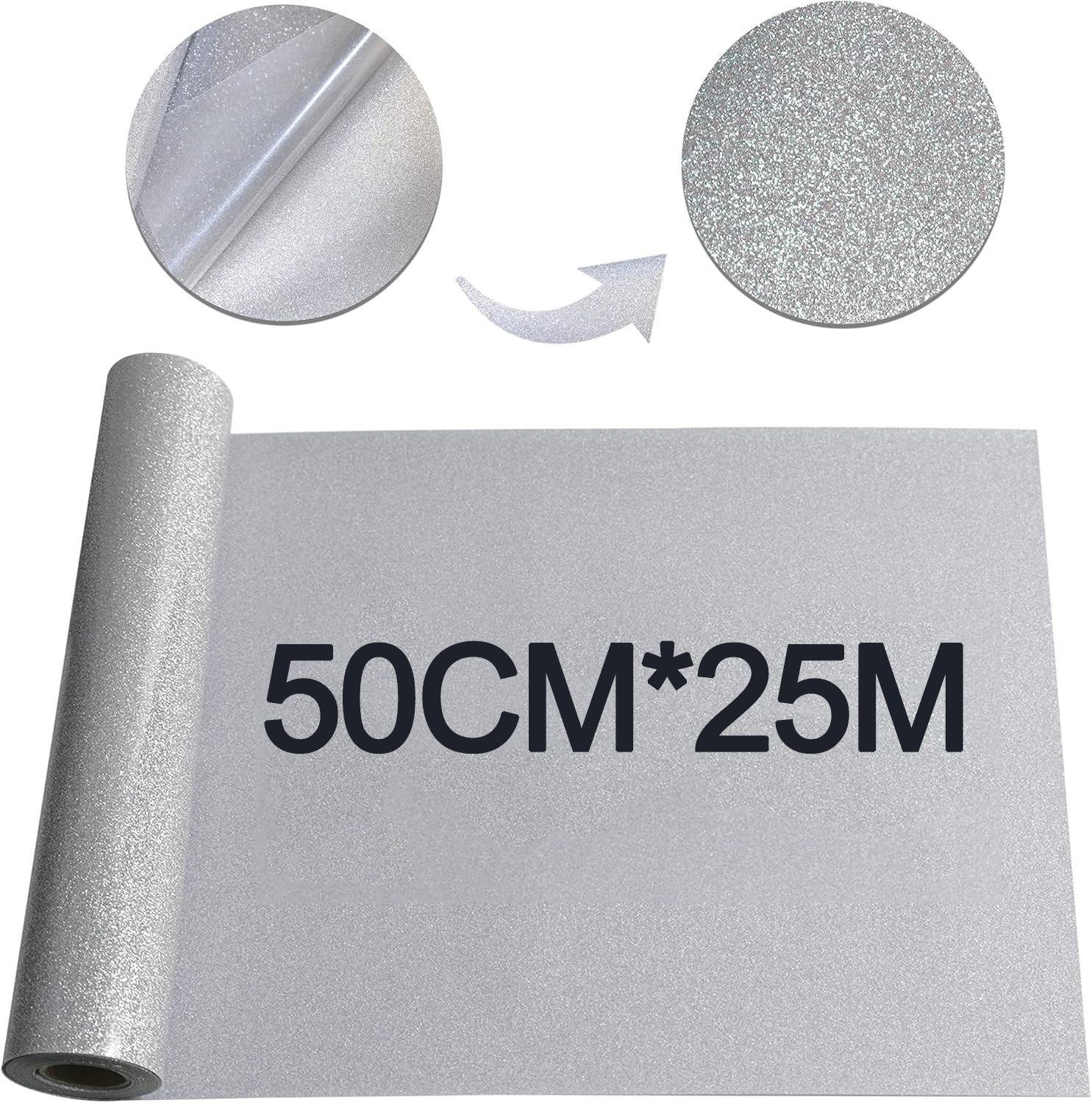

10. Storage of glitter vinyl transfer film: Store in a cool, dry place, avoid sharp objects, and seal any unused portions to prevent moisture and high temperatures.

11. Not testing a small sample before mass production: This can lead to quality issues in large-scale production. The solution is to test a small sample before mass production to ensure quality.

When using glitter vinyl transfer film, it is also important to use the correct transfer temperature and time, as well as the correct methods for transferring and peeling, to ensure the quality and effect of the final product.

上一篇:温变热转印刻字膜